A Comprehensive Study of Schedule 40 Pipe's Function in Modern Plumbing Solutions

- Adamjee DuraBuilt

- Jul 24, 2023

- 4 min read

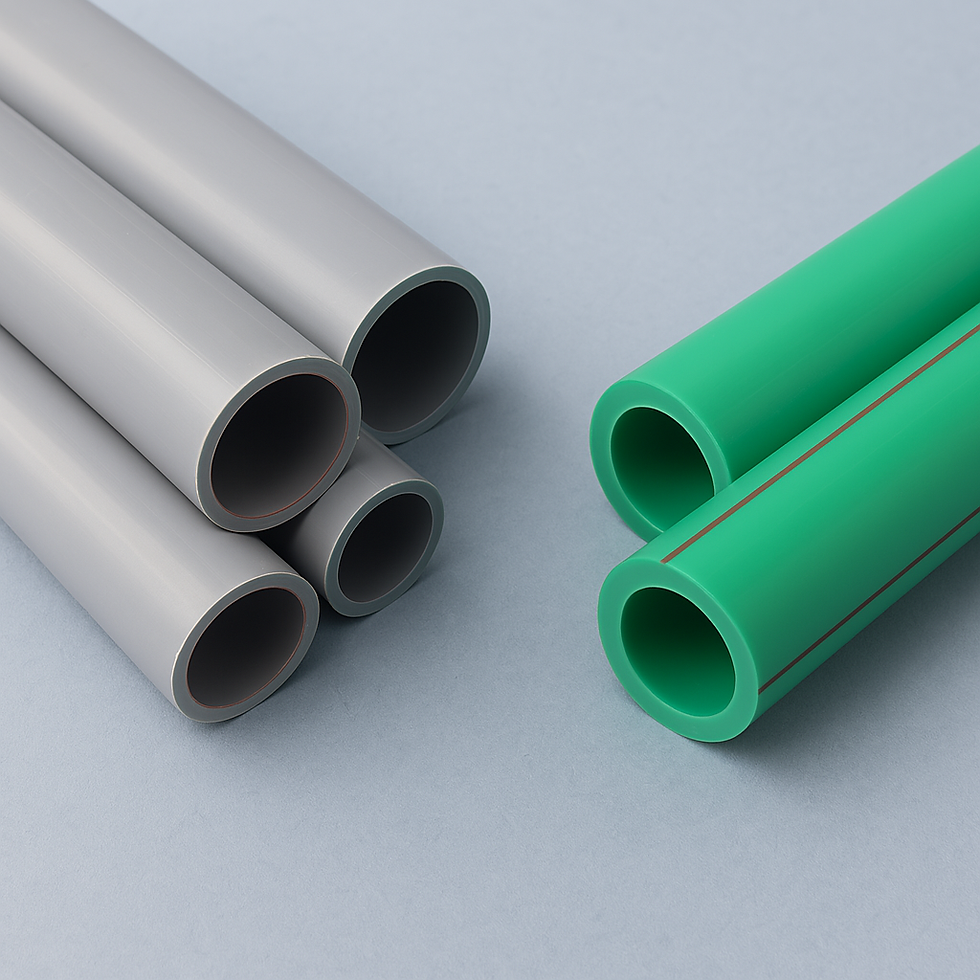

Schedule 40 pipe is a prime example of superior engineering in the field of contemporary plumbing, where effectiveness, sturdiness, and dependability are critical. Due to Schedule 40 pipe's uniform thickness, remarkable strength, and adaptability, it is now a necessity in a variety of plumbing applications. This pipe, which meets the needs of residential, commercial, and industrial customers, is made from high-quality PVC (Polyvinyl Chloride) material and provides a complete solution for water distribution, drainage, sewage systems, and more. As we learn more about plumbing technology, it becomes more and clearer that Schedule 40 pipe is crucial to delivering reliable and long-lasting solutions that raise the bar for contemporary plumbing to unmatched heights. We examine Schedule 40 pipe's many features in this thorough analysis, revealing its distinctive qualities and the vital part it plays in influencing the design of modern plumbing solutions.

Understanding Schedule 40 Pipe: What Sets It Apart?

Due to its regulated thickness and robust construction, Schedule 40 pipe is the preferred choice for residential, commercial, and industrial plumbing applications. It is known for its durability, pressure-bearing capacity, and corrosion resistance, all of which provide consistent performance over time. With a set wall thickness established by the schedule, this type of pipe can withstand both high and low-pressure applications, making it ideal for a range of plumbing tasks.

A Closer Look at Schedule 40 Pipe's Material and Composition

Schedule 40 pipe is often made from premium PVC (Polyvinyl Chloride) and is designed to adhere to rigid industry standards. It can endure a variety of climatic elements and extreme situations thanks to its composition, which makes it resistant to chemicals, UV radiation, and abrasions. The Schedule 40 pipe is made of PVC, which has exceptional insulating qualities. This means that it can transport both hot and cold water without losing structural integrity.

Applications of Schedule 40 Pipe in Plumbing Systems

The use of schedule 40 pipe is widespread in a variety of plumbing applications. It demonstrates its adaptability and effectiveness in residential, commercial, and industrial contexts through the distribution of potable water as well as drainage, sewer systems, irrigation, and more. Excellent flow characteristics and a smooth interior surface of the pipe reduce pressure loss and guard against blockages to ensure effective water flow in a variety of plumbing systems. Furthermore, it makes installation simpler and enables smooth integration into plumbing networks thanks to its compatibility with a variety of fittings and connectors.

Why Choose Schedule 40 Pipe for Plumbing Projects?

We look at the strong arguments for why Schedule 40 pipe is the preferred choice for plumbing projects. It is a dependable and useful option due to its affordability, simplicity of installation, low maintenance requirements, and capacity to manage demanding circumstances. The Schedule 40 pipe's uniform dimensions guarantee compatibility with a range of fittings and fixtures, facilitating installation and obviating the need for special parts. Additionally, the interior's smooth surface reduces friction, promoting effective water flow and lowering the possibility of clogs or obstructions. A pipe is a great option for both residential and commercial plumbing applications because of its remarkable durability and resistance to corrosion, which makes it a cost-effective investment that ensures long-term performance.

Ensuring Longevity and Reliability: Maintenance Tips for Schedule 40 Pipe

The performance and longevity of Schedule 40 pipe must be preserved through proper maintenance. To ensure that the pipe performs ideally for the duration of its service life, this section offers helpful advice on examining, maintaining, and caring for the pipe. Regular visual inspections can aid in the early detection of potential problems like leaks or cracks, enabling prompt repairs. The interior of the pipe should be cleaned routinely to eliminate any collected material, which helps to prevent blockages and ensure constant water flow. The pipe's resistance to environmental elements like temperature changes or UV radiation can also be improved by putting protective coatings or insulation, further ensuring its dependability and endurance in plumbing systems.

Comparing Schedule 40 Pipe with Other Plumbing Materials

We compare Schedule 40 pipe to various plumbing components in this section, including Schedule 80 pipe, copper, and PEX. We contrast their benefits and drawbacks to enable readers to choose wisely depending on their unique project requirements. Schedule 80 pipe offers even better durability and resistance to higher pressures whereas Schedule 40 pipe boasts remarkable strength and pressure-bearing capacity. The increased heat conductivity and antibacterial qualities of copper pipes, on the other hand, make them ideal for some particular applications. PEX pipes are favored options for home plumbing projects because of their adaptability and simple installation. Readers may make well-informed decisions that fit their plumbing needs and financial limits by being aware of the distinctive characteristics of each material.

Sustainability and Eco-Friendly Features of Schedule 40 Pipe

The advantages of Schedule 40 pipe for the environment have gained attention as the importance of sustainability and environmentally friendly operations has increased. This plumbing material has a number of important qualities that support sustainability, which makes it a desirable option for projects that care about the environment.

Recyclability: PVC, a thermoplastic material that is recyclable, is used to make Schedule 40 pipe. This implies that the pipe can be recycled and used again once its useful life is up, lowering the need for raw materials and lowering waste production. Recycling PVC as part of the circular economy makes a substantial contribution to resource and environmental preservation.

Energy Efficiency During Manufacturing: The procedure used to create Schedule 40 pipe is energy-efficient. PVC manufacturing uses less energy than the production of various other plumbing-related materials, thus lowering its environmental impact. People and companies can indirectly promote energy-efficient manufacturing techniques and help reduce industry-wide energy usage by selecting Schedule 40 pipe for plumbing projects.

Potential Contribution to Green Building Initiatives: Schedule 40 pipe can aid in achieving sustainability objectives as the plumbing and construction sectors increasingly adopt green building programs. Schedule 40 pipe is an example of an eco-friendly material that can help construction projects seeking green certifications like LEED (Leadership in Energy and Environmental Design) gain points. Additionally, because this pipe satisfies the standards for resource efficiency and environmental performance, utilizing it is consistent with sustainable building methods.

Conclusion:

Finally, Schedule 40 pipe has become a key component of contemporary plumbing solutions. Its outstanding qualities, including dependability, affordability, simplicity of installation, and environmental considerations, make it an essential option for a variety of applications. Schedule 40 pipe continues to influence plumbing technology, assuring effective and dependable plumbing systems for future generations, whether for residential, commercial, or industrial projects.

Comments