Is HDPE the Best Pipe Option for Underground Water Lines?

- Adamjee DuraBuilt

- Jun 18, 2025

- 5 min read

1. Introduction: The Need for Reliable Underground Water Line Solutions

As populations grow and infrastructure ages, the demand for durable underground water lines has never been higher. In both urban and rural settings, failing water lines often lead to costly repairs, water loss, and contamination. The World Bank estimates that up to 30% of urban water is lost through leaks in distribution systems, primarily due to outdated materials and poor infrastructure. In Pakistan, cities like Lahore and Karachi are already facing water distribution challenges due to pipeline deterioration.

HDPE pipes and fittings in Pakistan have emerged as a revolutionary solution to these problems. With superior resistance to corrosion, extreme weather, and mechanical stress, HDPE technology is rapidly becoming the backbone of modern water infrastructure. But is HDPE truly the best choice for underground water lines? Let's find out.

2. What Is HDPE and Why Is It Used for Piping?

High-Density Polyethylene (HDPE) is a thermoplastic polymer known for its high strength-to-density ratio. It's lightweight yet tough and resistant to both chemical and physical degradation. Initially developed in the 1950s, HDPE is now widely used in piping systems due to its longevity and performance.

Key Properties:

Flexibility: Can bend without breaking, ideal for varied terrain

Non-toxic: Safe for potable water

Corrosion-resistant: No rust or scaling like metal pipes

UV-stable (with additives): Withstands sun exposure during above-ground transport

These features make HDPE pipes ideal for underground installations where longevity, hygiene, and performance are essential.

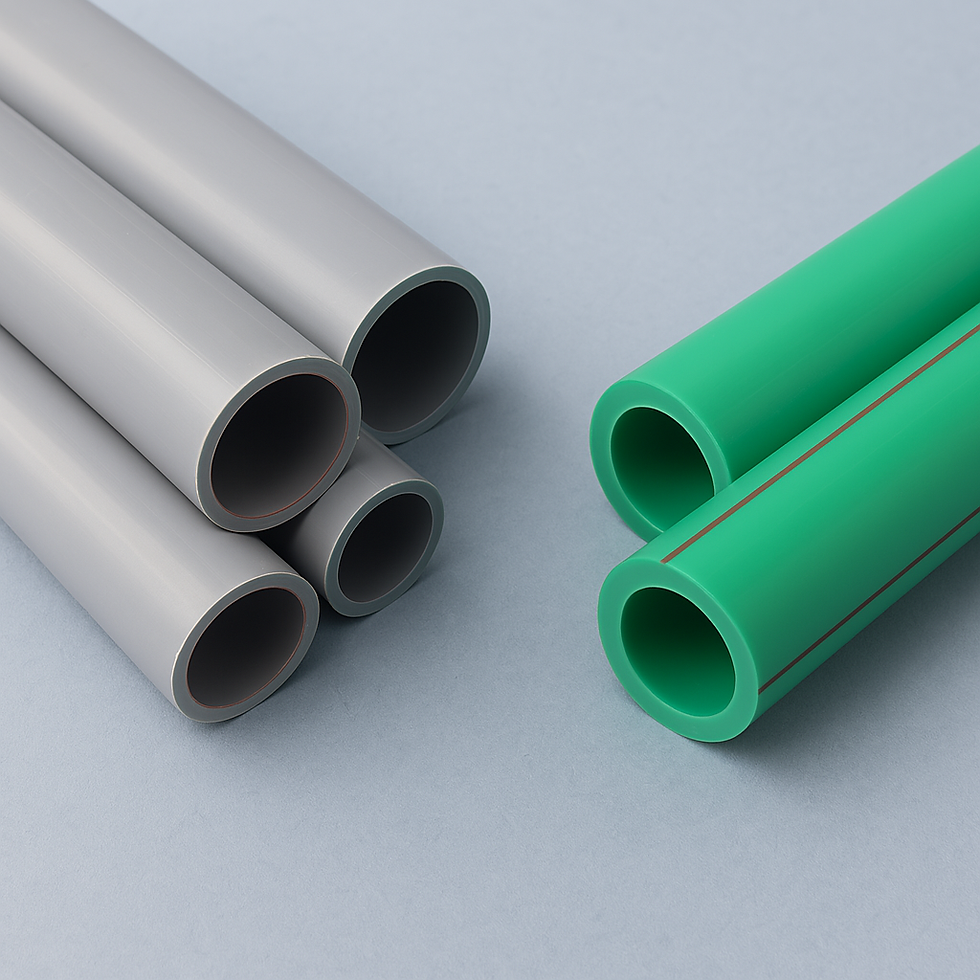

3. Common Materials Used for Underground Water Lines: A Comparison

When selecting a piping material, it's important to consider durability, installation cost, and maintenance. Here's how HDPE stacks up:

PVC Pipes:

Affordable and easy to install

Brittle in cold conditions

Joints may leak over time

Ductile Iron Pipes:

Very strong under pressure

Susceptible to corrosion without coating

Heavy and expensive to install

Copper Pipes:

Excellent for small residential systems

Very expensive

Can corrode depending on water quality

Concrete Pipes:

Durable for large diameter use

Not ideal for small-scale or uneven terrain

HDPE Pipes:

Fusion-welded for leak-free performance

Lightweight and flexible

Long lifespan (50–100 years)

Easy trenchless installation

HDPE outperforms in harsh environments and complex installations, making it the preferred material in many municipal and rural applications.

4. Key Advantages of HDPE Pipes in Underground Water Systems

1. Leak-Free Performance

HDPE pipes use butt fusion or electrofusion joining, which creates a monolithic, seamless system. This virtually eliminates leaks.

2. Flexibility for Uneven Terrain

HDPE can bend around obstacles and follow the landscape. This reduces the need for joints and fittings, which are potential points of failure.

3. Corrosion & Chemical Resistance

Unlike steel or iron, HDPE doesn't rust. It's immune to most chemicals found in soils and groundwater.

4. Long Life Expectancy

According to the Plastic Pipe Institute (PPI), HDPE systems can last over 100 years under optimal conditions.

5. Trenchless Technology Compatible

HDPE is suitable for horizontal directional drilling (HDD) and pipe bursting—methods that minimize surface disruption and lower installation costs.

6. Lightweight & Easy to Transport

Its lightweight makes it easier and cheaper to transport and install, even in remote areas.

5. Disadvantages or Limitations to Consider

Despite many advantages, HDPE isn’t without a few limitations:

Higher Initial Cost: Material and fusion equipment can be more expensive upfront.

Requires Skilled Labor: Fusion joining must be done by trained personnel.

UV Sensitivity: Prolonged exposure to sunlight degrades unprotected HDPE, requiring UV stabilizers.

Pressure Limitations: In very high-pressure systems, thicker walls are required.

However, these downsides are often outweighed by the reduced maintenance, long life, and performance benefits.

6. Real-World Applications: HDPE in Action

Global Success Stories:

USA: Cities like Portland and Los Angeles use HDPE for water supply and fire protection systems.

Germany: Municipalities use HDPE extensively for gas and water networks.

UAE: HDPE is a standard for water lines in desert and coastal cities due to corrosion resistance.

In Pakistan:

In Pakistan, HDPE pipes have seen widespread use in water distribution projects, particularly in areas with difficult terrain. Agricultural districts in Punjab use HDPE for irrigation lines due to its flexibility and cost-efficiency over time.

7. Environmental and Health Safety

HDPE is not only safe but also sustainable:

Non-toxic and BPA-free: Approved by WHO for potable water.

No leaching: Maintains water purity.

Recyclable: Can be repurposed into new pipes or plastic products.

Low Energy Manufacturing: Has a lower carbon footprint compared to metal pipes.

This makes HDPE a responsible choice for modern infrastructure projects.

8. HDPE Pipes and Fittings: A Seamless System

HDPE pipes function best when paired with compatible fittings like elbows, tees, and reducers. These fittings are also made from HDPE and are joined through fusion welding, ensuring the same leak-free performance across the system.

The availability of HDPE pipes and fittings in Pakistan has grown significantly, making it easier for builders and homeowners to adopt this advanced system.

9. Expert Recommendations: When Should You Choose HDPE?

Choose HDPE pipes if your project includes:

Remote or rural installations where transporting heavy materials is difficult.

Unstable or shifting soil conditions where flexibility is crucial.

Trenchless installations minimize road or land disruption.

Municipal water systems require long-term performance.

Agricultural pipelines need chemical and pressure resistance.

HDPE is also a strong contender for retrofitting older systems without massive excavation.

10. Final Verdict: Is HDPE the Best Pipe for Underground Water Lines?

In most scenarios, HDPE pipes outshine traditional materials. Their adaptability, strength, longevity, and environmental safety make them a superior choice for underground water lines.

Although initial costs and welding expertise can be hurdles, the long-term benefits—like minimal maintenance, fewer replacements, and leak prevention—make HDPE the best choice for forward-thinking infrastructure.

If you're planning a water project, consult with HDPE suppliers or civil engineers to assess your specific needs. In a rapidly urbanizing world, future-proofing water infrastructure starts with the right piping solution.

FAQs About HDPE Pipes for Underground Use

Q1: Can HDPE pipes be used for drinking water?

Yes. HDPE is certified safe for potable water and is widely used in drinking water systems worldwide.

Q2: How long do HDPE pipes last underground?

Under normal conditions, HDPE pipes can last 50–100 years, depending on usage and soil chemistry.

Q3: Are HDPE pipes better than PVC for water lines?

Yes, especially in underground applications. HDPE offers better flexibility, fusion-welded joints, and higher resistance to impact and corrosion.

Q4: What is the cost difference between HDPE and traditional pipes?

HDPE may have a higher initial cost, but the total lifecycle cost is lower due to reduced maintenance and longer lifespan.

Q5: Where can I find HDPE pipes and fittings in Pakistan?

HDPE pipes and fittings in Pakistan are widely available through reputable manufacturers and distributors like Adamjee Dura Built, ensuring quality and compliance with international standards.

Want help choosing the right HDPE pipe system for your project? Contact a certified supplier today and invest in long-term water system success.

Comments