Why UPVC and PPRC Pipes Are Preferred for Drinking Water Applications

- Adamjee DuraBuilt

- Apr 9, 2025

- 5 min read

1. Introduction

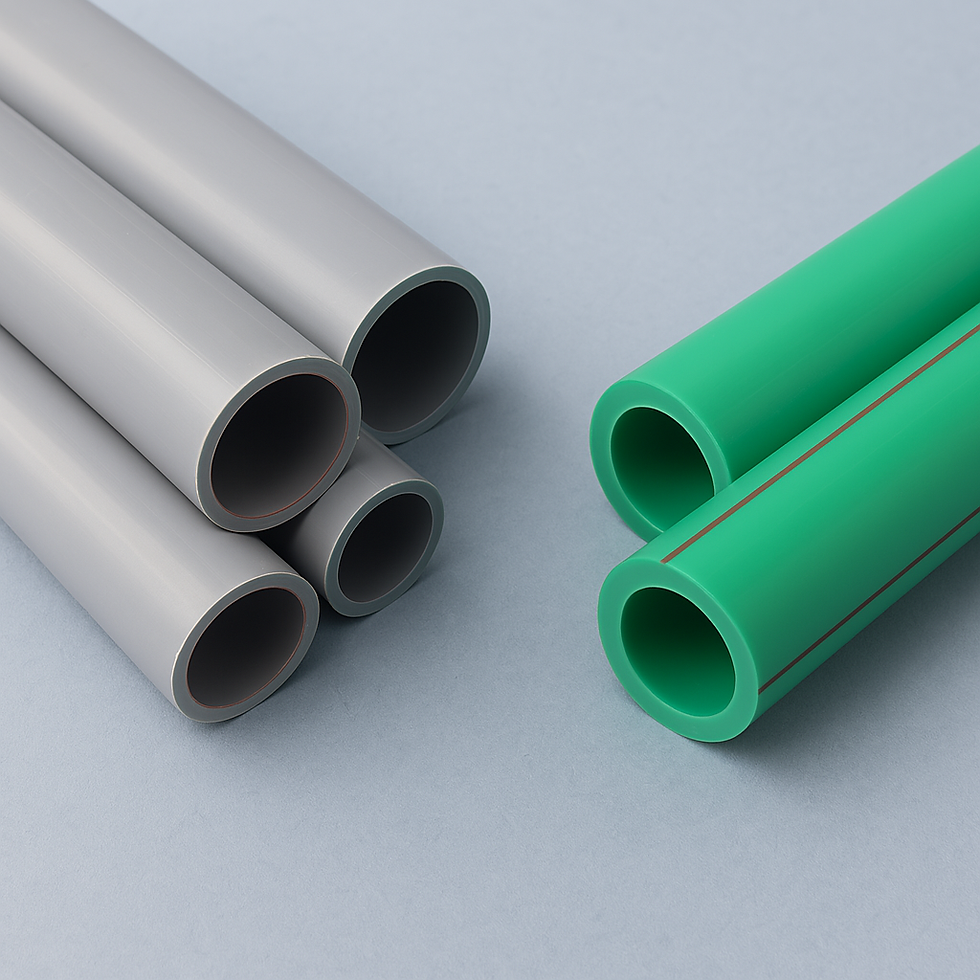

Safe and clean drinking water is essential for every infrastructure project. Choosing the right piping material ensures water quality, reduces maintenance, and extends system life. When it comes to modern drinking water systems, UPVC pipes and PPRC pipes are two of the most trusted options. Their exceptional properties make them ideal for residential, commercial, and industrial water supply projects.

In this article, we'll dive deep into why UPVC and PPRC pipes have become the preferred solutions for drinking water applications. Whether you're an infrastructure professional, a construction expert, or a plumbing specialist, understanding these materials is critical for delivering reliable and safe water systems.

2. Understanding the Requirements of Drinking Water Systems

Designing a drinking water system demands materials that guarantee:

Health and safety compliance: Pipes must be non-toxic and safe for potable water as per WHO and local standards.

Corrosion resistance: No degradation when exposed to water or minerals.

Temperature and pressure resistance: To handle varying environmental and operational conditions.

Longevity: Pipes should last decades with minimal deterioration.

Cost-effectiveness: Affordable installation and maintenance without compromising quality.

UPVC and PPRC pipes fulfill these crucial requirements better than many traditional materials like galvanized iron or copper.

3. What Are UPVC Pipes?

UPVC stands for Unplasticized Polyvinyl Chloride. Unlike regular PVC, UPVC is free from plasticizers, making it more rigid and durable.

Key Features of UPVC Pipes:

Non-toxic and chemical resistant: Ensures water purity without harmful leaching.

Smooth inner surface: Promotes smooth water flow and reduces sediment buildup.

Lightweight and easy to install: Reduces labor costs and speeds up project timelines.

UV resistance: Ideal for outdoor installations when protected appropriately.

High pressure handling: Suitable for large-scale water distribution systems.

UPVC pipes and fittings are widely used for cold water applications in residential and commercial sectors.

4. What Are PPRC Pipes?

PPRC stands for Polypropylene Random Copolymer. These pipes are designed for versatile plumbing needs, offering superior resistance to temperature and pressure.

Key Features of PPRC Pipes:

Excellent thermal stability: Can withstand high temperatures up to 95°C.

Corrosion and scale resistance: Maintains smooth water flow for decades.

Heat fusion joints: Creates leak-proof, strong connections.

Suitable for hot and cold water: Ideal for all drinking water systems.

Eco-friendly and recyclable: Reduces environmental impact.

Due to these properties, PPRC pipes are rapidly becoming the top choice in pprc pipes and fittings in Pakistan and globally.

5. Why UPVC Pipes Are Preferred for Drinking Water Applications

5.1. Non-Toxic and Safe Material

UPVC pipes and fittings are manufactured without any harmful chemicals. They don't react with drinking water, ensuring that the water remains pure and safe for consumption. Their compliance with international health standards makes them a trusted material worldwide.

5.2. Corrosion and Chemical Resistance

Unlike metal pipes, UPVC pipes do not corrode, pit, or scale. They resist the chemical compositions found in various water sources, maintaining system integrity over decades.

5.3. High Durability and Longevity

With a life expectancy of more than 50 years, UPVC pipes and fittings are built for the long haul. They withstand physical impacts, pressure variations, and environmental factors better than many alternatives.

5.4. Cost-Effectiveness

UPVC pipes are not just affordable initially; their long lifespan, minimal maintenance, and easy installation make them highly cost-effective in the long term.

6. Why PPRC Pipes Are Preferred for Drinking Water Applications

6.1. Superior Thermal Resistance

PPRC pipes can comfortably handle water temperatures as high as 95°C. This makes them ideal for hot and cold potable water systems, especially in industrial and commercial settings.

6.2. Leak-Proof Installation

Thanks to heat fusion welding, joints in PPRC pipes become completely homogenous. This leak-proof system ensures maximum reliability and reduces water loss.

6.3. Resistance to Biofilm Formation

The smooth internal surface of PPRC pipes discourages the accumulation of microorganisms and biofilms, maintaining high water quality and hygiene standards.

6.4. Environmentally Friendly

PPRC is 100% recyclable. Its manufacturing and disposal have a significantly lower environmental footprint compared to traditional piping materials.

These advantages have made pprc pipes and fittings in Pakistan a highly demanded choice in modern water supply systems.

7. Comparison Between UPVC and PPRC Pipes for Drinking Water Systems

Here’s a quick comparison to help professionals choose between the two:

Feature | UPVC Pipes | PPRC Pipes |

Temperature Resistance | Up to 60°C | Up to 95°C |

Jointing Method | Solvent Cement | Heat Fusion |

Corrosion Resistance | High | Very High |

Application | Cold Water | Hot & Cold Water |

Lifespan | 50+ Years | 50+ Years |

Installation Ease | Very Easy | Skilled Labor Needed |

Cost | Lower | Slightly Higher |

Both UPVC and PPRC pipes are excellent, but choosing between them depends on project-specific needs.

8. Applications of UPVC and PPRC Pipes in Drinking Water Systems

Both piping systems are versatile and widely used in:

Residential Water Supply: Apartments, homes, and housing societies.

Commercial Complexes: Hotels, office buildings, shopping malls.

Healthcare Facilities: Hospitals and clinics demanding hygienic systems.

Industrial Water Systems: Factories and processing plants.

Rural and Urban Infrastructure Projects: Government-funded potable water schemes.

These applications highlight how integral UPVC and PPRC pipes have become to reliable water delivery.

9. Key Considerations When Choosing Between UPVC and PPRC Pipes

Before finalizing pipe material, assess the following:

Water Temperature Requirements: Use UPVC for cold water; PPRC is better for both hot and cold water.

Project Budget: UPVC is more economical; PPRC offers additional features at a slightly higher cost.

Installation Expertise: UPVC installation is simple. PPRC requires skilled technicians for heat fusion joints.

Maintenance Needs: Both require minimal maintenance but consider accessibility and future repair needs.

Local Regulations and Certifications: Ensure the selected pipes meet local potable water standards.

Environmental Impact: If sustainability is a priority, PPRC’s recyclability might be more appealing.

Choosing carefully ensures better system performance and customer satisfaction.

10. Future Trends: Sustainable Water Supply Solutions

The global shift toward sustainable infrastructure is influencing the future of piping systems:

Eco-Friendly Innovations: Manufacturers are improving recycling processes and reducing energy consumption during production.

Smart Piping Systems: Integration with IoT devices to monitor water quality, pressure, and leaks is on the rise.

Enhanced Material Science: Research is underway to create even more durable, flexible, and efficient piping systems.

UPVC and PPRC pipes are already aligned with these trends, making them forward-compatible choices for upcoming projects.

11. Conclusion

Both UPVC and PPRC pipes have redefined the standards of drinking water systems. Their unmatched durability, safety, and cost-effectiveness make them the top choices among infrastructure professionals and plumbing specialists.

When deciding between UPVC and PPRC pipes, carefully evaluate the water temperature, project size, installation methods, and budget. Each offers unique advantages, but both ensure a clean, safe, and reliable water supply for decades.

As drinking water quality continues to be a global priority, choosing trusted solutions like PPRC pipes and UPVC pipes will remain critical for sustainable development.

Comments