The Ultimate Guide to PPRC Pipes: Applications, Installation, and Maintenance

- Adamjee DuraBuilt

- Aug 7, 2023

- 4 min read

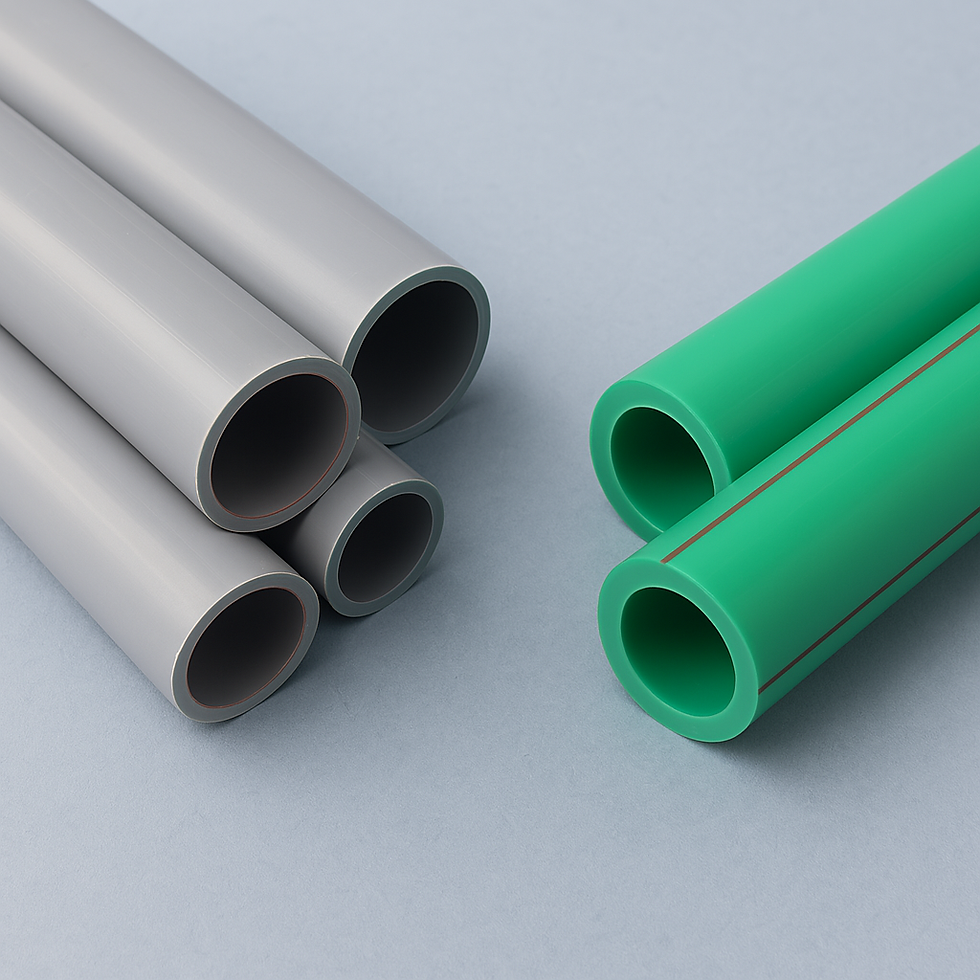

Modern plumbing and building projects frequently use plastic piping systems known as PPRC (Polypropylene Random Copolymer) pipes. These pipes have become recognized for their outstanding qualities, which include strong resistance to corrosion caused by chemicals, pressure, and temperature. Since PPRC pipes are frequently used to supply both hot and cold water, they can be used for a variety of applications in both residential and commercial as well as industrial settings. We will examine various applications, appropriate installation methods, and crucial maintenance procedures in this extensive guide to ensure the durability and effectiveness of PPRC pipes.

Applications of PPRC Pipes

Due to their flexibility and durability, PPRC pipes are used in a wide variety of applications. They are frequently utilized to give potable water to homes, hotels, hospitals, and schools. Additionally, PPRC pipes are widely used in industrial settings to transport corrosive liquids and a variety of chemicals. PPRC pipes are safe for conveying drinking water since they are non-toxic, protecting the health and welfare of locals. Additionally, PPRC pipes are used in underfloor heating systems because they resist high temperatures without losing structural integrity. They are the perfect option for long-lasting plumbing systems due to their great resistance to corrosion and scale.

Installation of PPRC Pipes

So as to ensure the best performance and lifetime of PPRC pipes, proper installation is essential. There are several critical steps in the installation procedure. In order to achieve connections without leaks, it is first necessary to cut the PPRC pipes precisely. For this, specialized PPRC pipe cutters are employed. The pipes are then carefully cleaned and deburred to get rid of any debris or jagged edges. The choice of high-quality, properly sized PPRC fittings is then made for connections that are secure. To establish fusion between the pipe and the fittings, a heated tool must be used. The heated components are tightly forced together to create a solid, leak-proof junction. To ensure that all connections are secure and dependable, the installation procedure should be carried out by experienced workers.

Maintenance of PPRC Pipes

PPRC pipes are recognized for requiring little maintenance. However, to maintain the plumbing system functioning at its best, regular inspections and maintenance procedures are required. There should be regular inspections for indications of leaks, cracks, or damage, and any problems should be resolved right once. When cleaning PPRC pipes, it's important to avoid using harsh chemicals or abrasive materials as this might cause the material to degrade. Instead, clean the pipes with soft cloths or sponges and light soap or cleaning agents. PPRC pipes can become brittle in extremely cold temperatures, so make sure the plumbing system is shielded from that as well. Damage can be avoided with proper insulation and routine inspections.

Advantages of PPRC Pipes

The outstanding thermal insulation capabilities of PPRC pipes are one of their main benefits. In contrast to metal pipes, PPRC pipes do not conduct heat, which reduces heat loss during the supply of hot water and makes them energy-efficient. This function not only lowers energy usage but also saves end users money. The internal surface of PPRC pipes is smooth and resistant to scaling and silt buildup. This feature guarantees a continuous flow of water, lowering the possibility of obstructions and maintaining steady water pressure.

The durability of PPRC pipes is another important benefit. These pipes are durable and reliable because of their excellent resistance to impact, chemical corrosion, and environmental conditions. PPRC pipes can last for many years without experiencing any performance decline with proper installation and upkeep. Their cost-effectiveness is increased by their durability, which means they need less replacement and upkeep over time. Additionally, PPRC pipes are recyclable and environmentally benign, helping to promote sustainable building methods and lessen their negative effects on the environment.

Key Considerations for PPRC Pipes Selection

There are a number of things to take into consideration while selecting PPRC pipes for your project. In the beginning, it's crucial to make sure the pipes and fittings are of good quality and follow industry requirements. Poor-quality materials can cause leaks and lower the plumbing system's overall effectiveness. Second, take into account the planned application and select the proper pipe diameter and thickness in accordance with it. Pipes that are the right size will provide ideal water pressure and flow. Collaborate with reliable manufacturers or suppliers who have a history of producing PPRC pipes and fittings of the highest caliber. Last but not least, get qualified plumbers or technicians to do the installation to make sure the pipes are attached correctly, reducing the chance of leaks, and assuring the durability of the plumbing system.

Future of PPRC Pipes in the Plumbing Industry

The future of PPRC pipes in the industry is bright as the demand for long-lasting, environmentally friendly plumbing solutions keeps growing. As production methods continue to progress, PPRC pipes are becoming more affordable and accessible, which makes them a desirable option for a variety of construction projects. PPRC pipes are an attractive alternative for environmentally aware developers and homeowners because of their eco-friendliness, which is in line with the increased emphasis on green building techniques. A top option in the plumbing business for years to come, PPRC pipes may further enhance their already remarkable qualities as technology develops.

Comments